Services

Detecting the presence of osmosis along the hull.

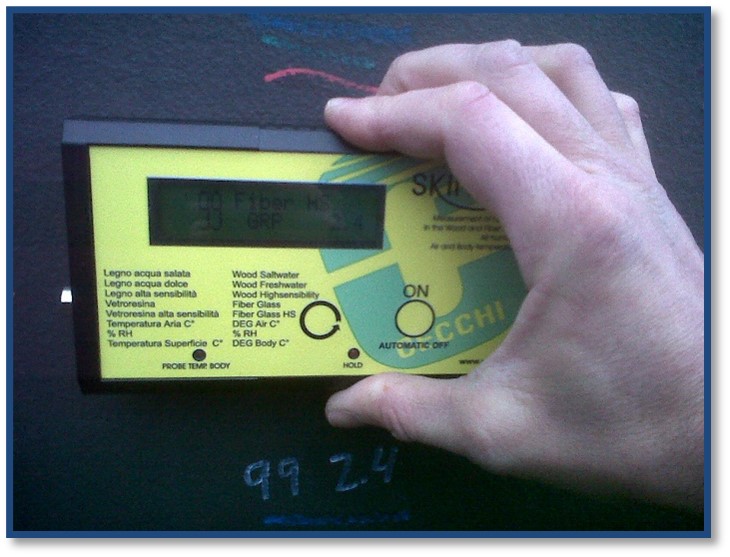

The visual analysis of a vessel’s hull allows to check if the gelcoat forms bubbles or presents irregularities, and in that case, attention must be paid because this could indicate the presence of osmotic processes. The first check to be carried out is an accurate inspection with a professional moisture meter to measure the humidity in various points along the hull.

It is important to know if the hull has undergone any repairs or osmotic treatments, especially if it is an older boat. The use of different materials such as putties or epoxy resins during refitting can only be detected through a Thermographic Inspection using Infrared Thermocameras, as the areas subjected to work and intervention exhibit different behaviors, especially through an Active Thermographic Inspection.

Infiltrations from sea intakes.

By using a professional moisture meter such as “Skinder”, it is possible to check the humidity levels of the hull both externally and internally near the sea intakes, and determine if there is an early delamination situation in fiberglass hulls. The professional moisture meter used also allows to verify if the fiberglass hull has osmosis issues by detecting the humidity levels in both fiberglass and wooden hulls.

The moisture meter has a calibration certificate issued by a Metrological Laboratory that guarantees and certifies the quality of the measurement results.

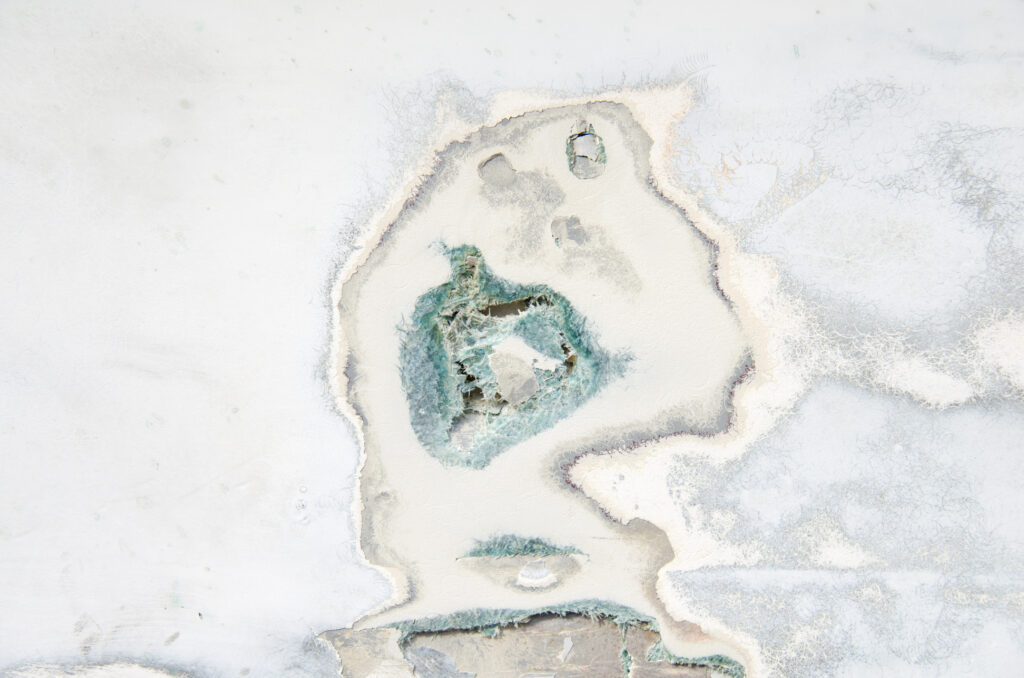

Delamination of a fiberglass hull.

The delamination of a sandwich fiberglass hull, which is made up of several layers of fiberglass with a balsa core to make the structure lighter, is caused by water ingress under one layer of fiberglass, causing detachment from the underlying element.

Through a Thermographic Analysis, it is possible to detect such problems along the hull or even along the deck of a vessel.

It is important to know if the hull has undergone any repairs or osmotic treatments, especially if it is an older boat. The use of different materials such as putties or epoxy resins during refitting can only be detected through a Thermographic Inspection using Infrared Thermocameras, as the areas subjected to work and intervention exhibit different behaviors, especially through an Active Thermographic Inspection.

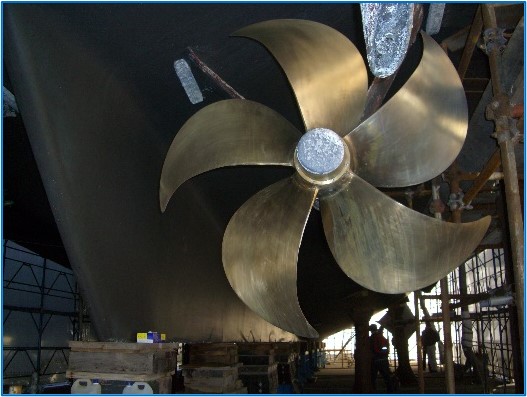

Corrosion of a metal hull.

The corrosion of a metal hull can be detected by taking measurements with an Ultrasonic Thickness Gauge, which allows us to detect thinning of the metal plates that make up the hull.

A good painting or passivation of surfaces exposed to the marine environment protect metal sheets from corrosion caused by external chemical agents, present in water and air.

The metal hull is also subjected to corrosion caused by electrochemical phenomena especially when the hull is in saltwater, since electrical conductivity is obviously greater, and galvanic corrosion can occur.

Therefore, it is necessary to conduct investigations using ultrasonic thickness gauges to ensure that there is no corrosion of the metal sheets of the hull or that the corrosion is not excessive and within certain limits.

Misurazione con Drone

The need to operate in environments that are not easily accessible by operators and the large size of the vessels to be analyzed has led us to equip ourselves with the latest generation technologies, using professional drones equipped with precision sensors and instrumentation for ultrasonic thickness investigations of hulls to assess corrosion or delamination, as well as for thermographic investigations but also visual investigations with high-resolution cameras.

Estimating damage from collisions

In case a vessel has suffered a collision with another boat, a pier or a rock, it is necessary to promptly assess the damage suffered in order to avoid the occurrence of enormous complications and worsening of the underwater part or even the topside, estimating the damage suffered and suggesting the necessary repairs to be carried out.